Rotative

Fill Seal 2000

Full Description

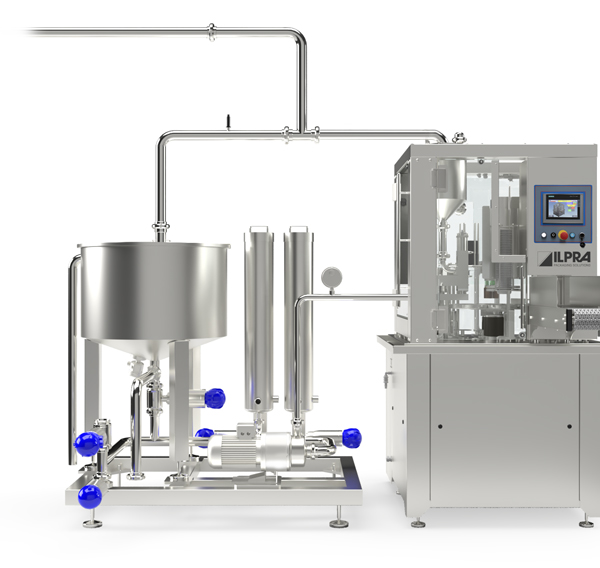

The Fill Seal 2000 is tailored for businesses seeking a compact and efficient pot filling and sealing solution. Its small footprint makes it suitable for operations with limited space, while its rotary table design ensures high productivity.

The machine’s touch screen panel allows for easy setting of working parameters and quick access to stored recipes, enhancing operational efficiency. Additionally, the Fill Seal 2000 is designed with user-friendliness in mind, making it accessible for operators with varying levels of experience.

Its robust construction and reliable performance make it an ideal choice for small to medium-sized businesses looking to streamline their pot filling and sealing processes, particularly in the dairy and condiment sectors. It is designed for efficiency and simplicity, with a configuration that includes one pot per station and a maximum output of 2,000 pieces per hour.

- Sealing -

Sealing Fill

Up to 35 cpm

Technical Data

Technical data : Fill Seal 2000

Dimensions : 166 x 101 x h 188 cm

Weight: Approx. 550 Kg

Installed electric power : 2,5 Kw

Electric power lid : -

Pots per cycle : 1

Ø Max Pots Lid : 125 mm

Ø Max Pots Film : -

Max Pots Height : 130 mm

Videos

Technology

Pick & Place

Automates the placement of pre-filled containers inside the machine, enhancing efficiency and reducing manual labor.

Suction of Foreign Materials

An air jet lifts any external bodies from the bottom of the container, which are then sucked up and removed, ensuring product purity.

Dosing Systems

Includes various types of dosers like volumetric, timed, drawer, flowmeter, providing flexibility and precision in filling.

Crimping System

Installed on the exit belt for glass or ceramic pot fillers, it crimps the lid to the side edge of the pot, ensuring a secure seal.

Inkjet

The Inkjet printer allows for the addition of important information like expiration date, production lot, etc., on the packaging, enhancing traceability and compliance.

DETAILS

Enhance Production

Explore Compatible Machines

Complete your production line with our range of automated packaging solutions.

Request a Quote

Get in touch here with our team to request a free quote. Our expert team will help you configure the best solution for your production line.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.