Rotative

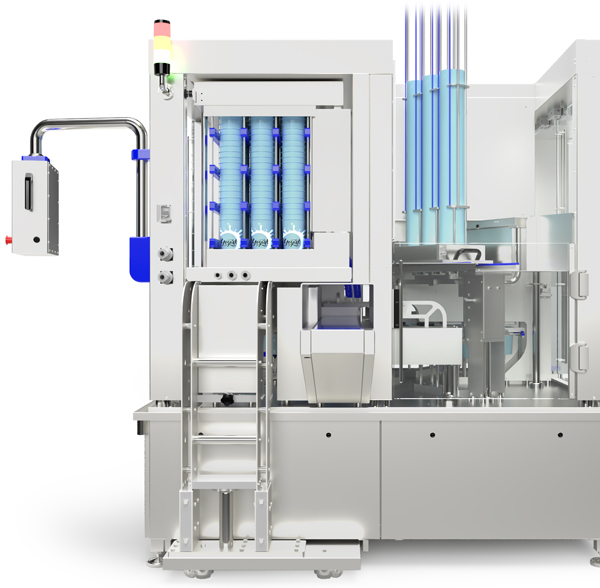

Fill Seal R12 & S12

Full Description

The Fill Seal R12 stands out for its advanced technology and high customization capabilities, making it suitable for businesses seeking a high-performance filling and sealing solution.

Its total brushless operation allows precise control over each step of the process, enhancing productivity and the careful handling of products and containers.

The S12 model, while more basic, still offers robust functionality and efficiency, making it a great option for businesses requiring a simpler solution. Both models are designed to handle various packaging methods, including sealing, gas flush, MAP/ATP, and vacuum, and can accommodate up to six pots per cycle.

- Sealing -

- Gas Flush -

- Vacuum -

- MAP/ATP -

Sealing

Up to 30 cpm

Gas Flush Fill

Up to 30 cpm

MAP/ATP Fill

Up to 20 cpm

Vacuum Fill

Up to 30 cpm

Sealing Fill

Up to 40 cpm

Technical Data

Technical data : Fill Seal R12

Dimensions : 215x 219x h 230 cm

Weight: circa 2900 Kg

Electric Power Lid: 11 Kw

Electric Power Film: 13 (N) - 16 (VG) kW

Pots per cycle: up to 6

Ø Max Cups Lid: 160 mm

Ø Max Cups Film : 160 mm

Max height Cup: 170 mm

Technical data : Fill Seal S12

Dimensions : 240 x 223 x h 232 cm

Weight: circa 2900 Kg

Electric Power Lid: 10,5 kW

Electric Power Film: -

Pots per cycle: up to 6

Ø Max Cups Lid: 160 mm

Ø Max Cups Film : -

Max height Cup: 170 mm

Videos

Technology

High-Capacity Storage

Optimizes the timing of each work step, increasing productivity and improving handling of products and containers.

Pick & Place

Automates the placement of pre-filled containers inside the machine, enhancing efficiency.

Suction of Foreign Materials

Removes foreign bodies from the bottom of containers, ensuring product purity.

Ultra Cleaning System

Offers sanitization options like UVC lamps, pulsed light, and hydrogen peroxide.

Dosing Systems

Provides a variety of dosing options for precise and efficient filling.

Laminar Flow Hood

Supplies a constant flow of micro-filtered air inside the machine to increase product shelf life.

Crimping System

Crimps the lid to the side edge of glass or ceramic pots, ensuring a secure seal.

Inkjet Printer

Adds essential information like expiration dates and production lots to packaging.

CIP Clean-In-Place System

Enables autonomous washing of the dosing unit, ensuring thorough cleaning and sanitization.

DETAILS

Enhance Production

Explore Compatible Machines

Complete your production line with our range of automated packaging solutions.

Request a Quote

Get in touch here with our team to request a free quote. Our expert team will help you configure the best solution for your production line.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.