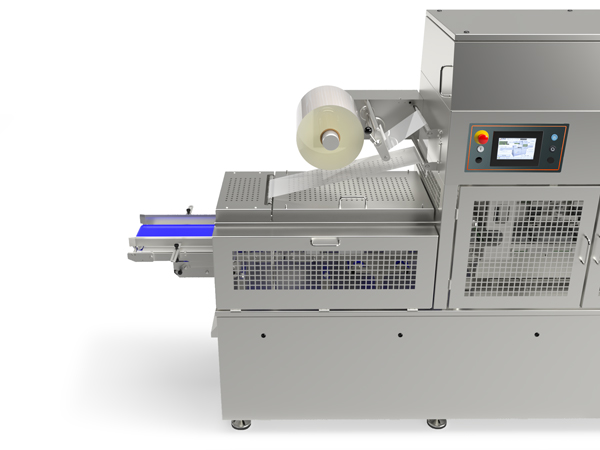

FoodPack 1485

The ultimate in automated tray sealing technology, the FoodPack 1485 is ideal for extensive production environments. It integrates CPS technology for synchronized operation of jaws and belts, ensuring peak efficiency. Its flexible design handles a range of packaging demands, including meats, fruits, ready meals, and beyond.

Its expansive sealing zone, fast cycle times, and straightforward design focus on maximizing space and air efficiency in high-traffic areas. The machine also features a sturdy construction, extending its lifespan and reliability in challenging settings. An easy-to-use interface decreases the need for extensive training, enhancing workflow. The precise sealing capability of the FoodPack 1485 maintains consistent quality, reinforcing brand reliability and consumer satisfaction.

E-MEC Technology

Leverages electromechanical motion to heighten speed and productivity.

PROGAS System

Patented technology that conserves gas while accelerating speed.

Constant Placement System

Enhances tray inflow and production speed.

Optional: ID Control System

Badge system for identifying authorized personnel.

Optional: ExtraSkin System

Enables skin packaging for items with substantial protrusion.

Optional: Pre-Heating System

Enhances packing efficiency through film pre-heating.

Optional: Predictive Maintenance System

Schedules maintenance and part replacements.

Optional: Anti-Crush System

Monitors tray alignment to prevent sealing errors.

Product Gallery

DETAILS