Semi-automatics

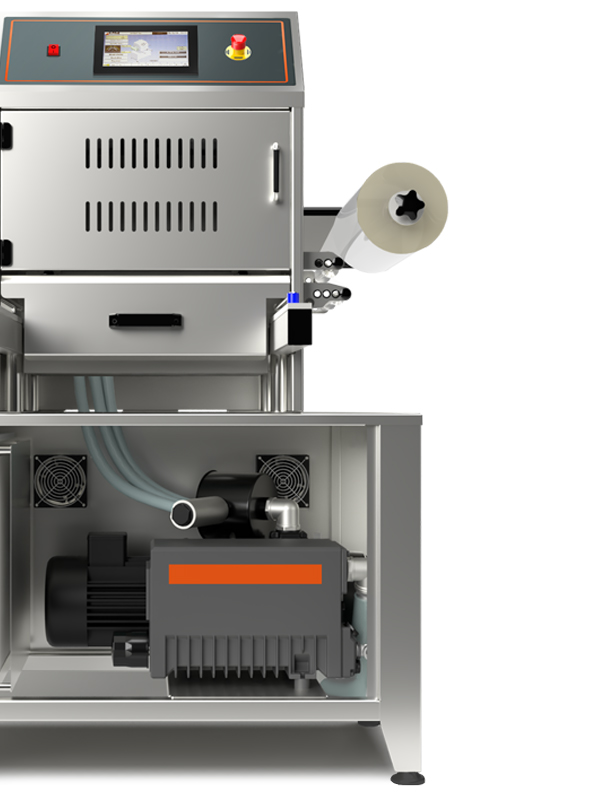

FoodPack 400 Extra

Full Description

The FoodPack 400 Extra is tailored for businesses that require a versatile and efficient packaging solution without a large investment. Its ability to handle up to six different types of packaging, including sealing only, MAP, vacuum, and various skin packaging options, makes it a highly adaptable machine for a range of products. The integrated touch screen panel allows for easy setting of working parameters and storage of several recipes, enhancing operational efficiency.

The compact design, including an internal vacuum pump, ensures that the machine occupies minimal space, making it suitable for environments with limited room.

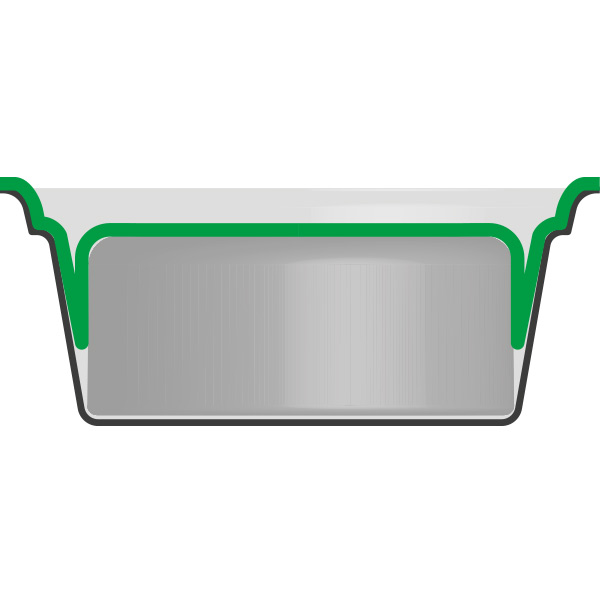

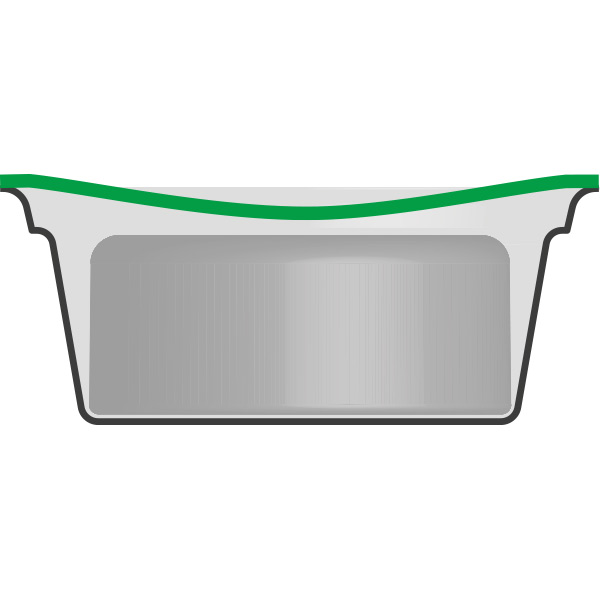

Sealing

MAP/ATP

Gas Flush

Skin

Vacuum

Overskin

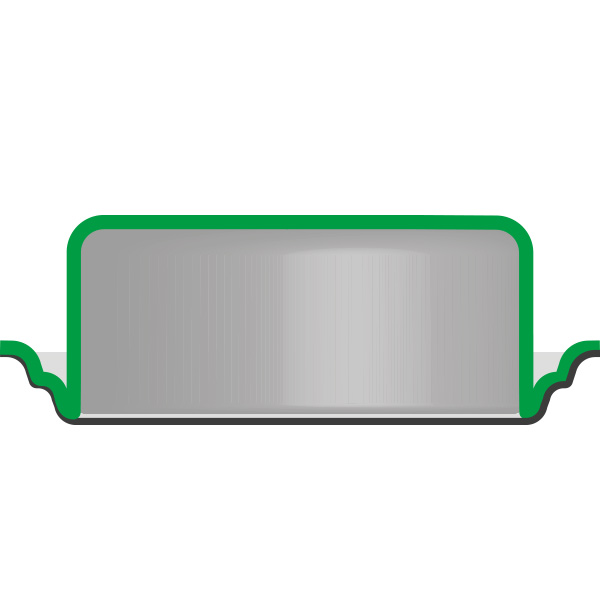

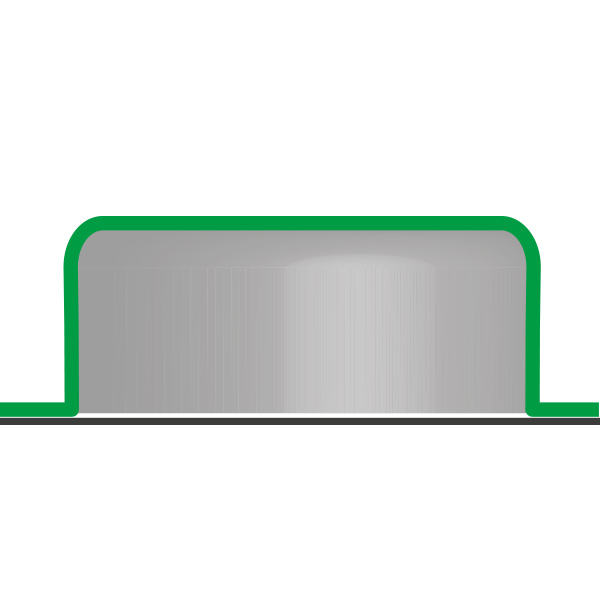

Extraskin

Extraskin on Cardboard

Technical Data

Technical Data: FoodPack 400 Extra

Dimensions: 105 x 108 x h 155 cm

Weight : approx. 400 Kg

Air Consumption Vacuum Gas: 6 bar - 35 Nlt/cycle

ExtraSkin Air Consumption : 6 bar - 80 Nlt/cycle

Vacuum Gas Sealing Area: 420 x 300 x h 135 mm

ExtraSkin Sealing Area : 400 x 300 x protrusion 50 mm (optional 70 mm)

Videos

Technology

PROGAS System

This innovative technology, patented by ILPRA, significantly reduces gas usage while enhancing the speed of the packaging process, contributing to both cost savings and increased productivity.

ExtraSkin

Specialized for high protrusion skin packaging, this technology allows for skin packing at up to 60 mm (optional 70 mm), providing flexibility and quality in packaging options, especially for products requiring enhanced presentation and protection.

DETAILS

Enhance Production

Explore Compatible Machines

Complete your production line with our range of automated packaging solutions.

Request a Quote

Get in touch here with our team to request a free quote. Our expert team will help you configure the best solution for your production line.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.