FoodPack Basic

FoodPack Basic is an ideal solution for businesses starting with tray sealing or with smaller production volumes. Its compact design allows it to fit easily in limited spaces, while still offering a range of packaging options including sealing, MAP/ATP, and vacuum. The Roto Basic version enhances productivity by allowing simultaneous loading/unloading and sealing/cutting operations. The E-Mec version further adds to the machine’s efficiency with its electromechanical movement. The touch screen panel simplifies operation and allows for the storage of multiple recipes, facilitating quick changes between different packaging needs.

Suitable for packaging a variety of food products such as pasta, meat, fish, and ready meals, the FoodPack Basic is also available in a Roto Basic version with a rotary table and an E-Mec version.

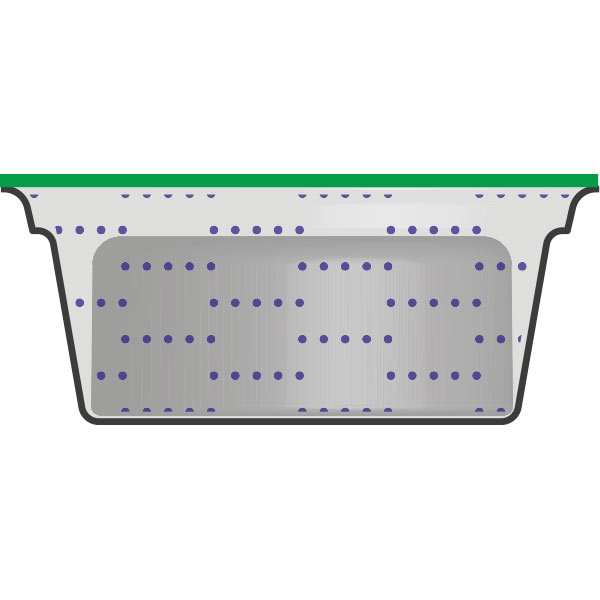

PROGAS System

The ProGas System is a patented technology developed by ILPRA, designed to enhance the efficiency and speed of the packaging process. This innovative system works by optimizing the use of gas in the packaging, ensuring that lower amounts are used without compromising the quality of the packaging atmosphere.

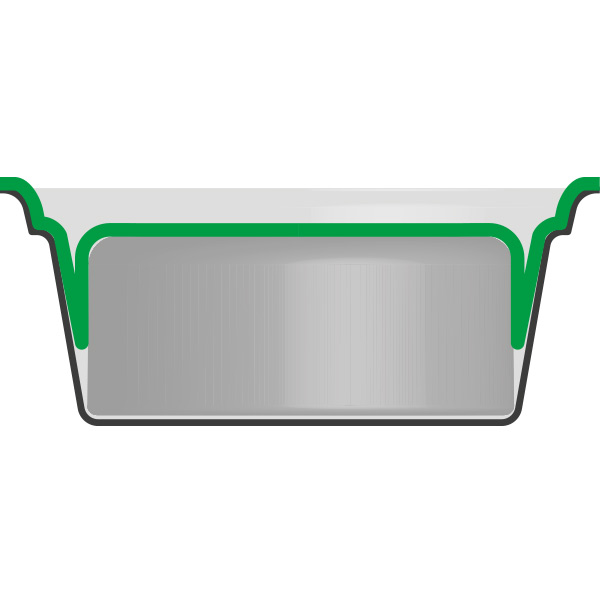

Optional: E-MEC Technology

Based on the fully electromechanical movement of the working station, this technology enables higher speed and productivity, offering an efficient solution for businesses looking to enhance their packaging processes.

Product Gallery

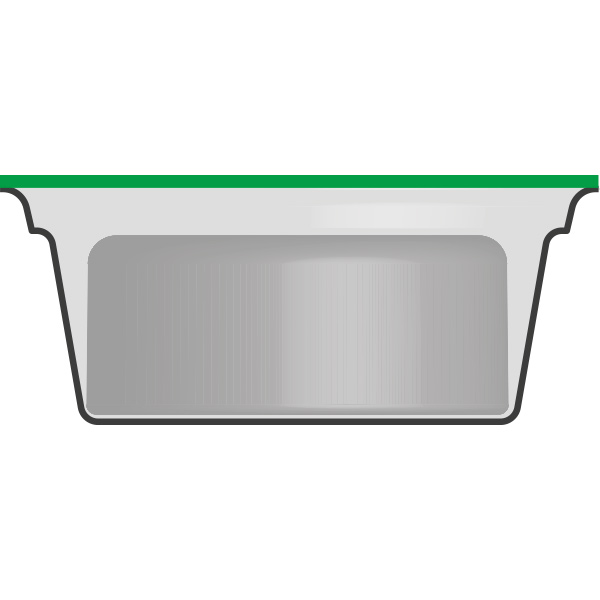

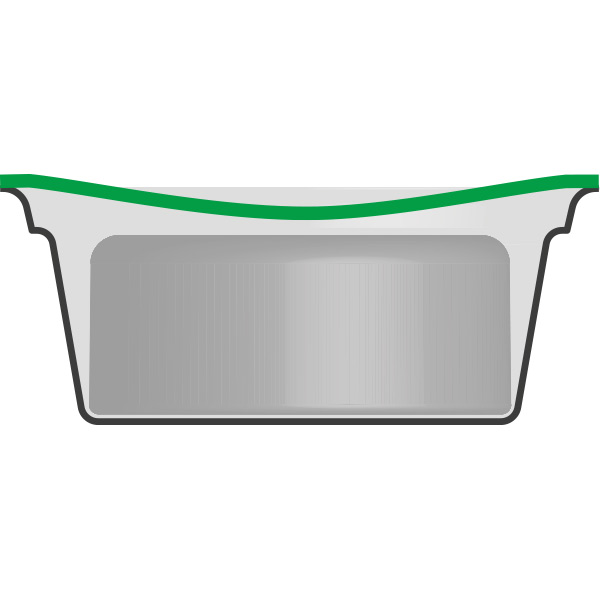

DETAILS