Bucket Line

FoodPack Buckets Line

Full Description

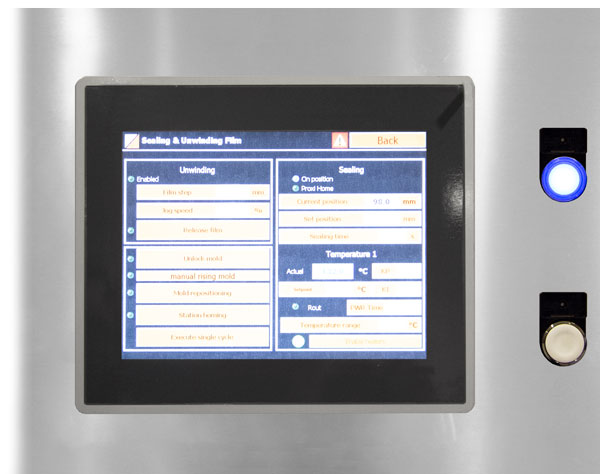

Designed for versatility and efficiency, this line is ideal for businesses looking for a comprehensive and adaptable bucket packaging system. The FoodPack Buckets Line stands out with its ability to automatically adjust the working height as programmed, ensuring optimal ergonomics and efficiency. The line’s high customizability allows for the integration of various accessories, such as material sanitization systems, gas flushing, partial vacuum, weight control, and sealing control. This makes it suitable for a wide range of applications and industries that require precise and reliable bucket packaging. The combination of advanced technology and customizable features positions the FoodPack Buckets Line as a top-tier solution for businesses seeking to enhance their packaging processes.

Sealing

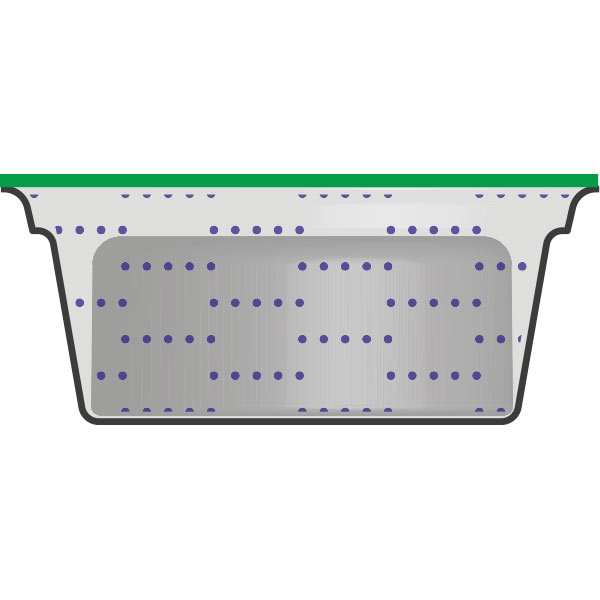

MAP/ATP

Vacuum

Gas Flush

Technical Data

Technical data: FoodPack Buckets Line

Dimensions: 750 x 140 x h 200 cm

Weight: approx. 3800 Kg

Air consumption: 6 bar - approx. 6 Nlt/cycle

Sealing area: diametro 330 mm x h 320 mm

Videos

DETAILS

Enhance Production

Explore Compatible Machines

Complete your production line with our range of automated packaging solutions.

Request a Quote

Get in touch here with our team to request a free quote. Our expert team will help you configure the best solution for your production line.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.