Bucket Line

FoodPack Speedy Buckets

Full Description

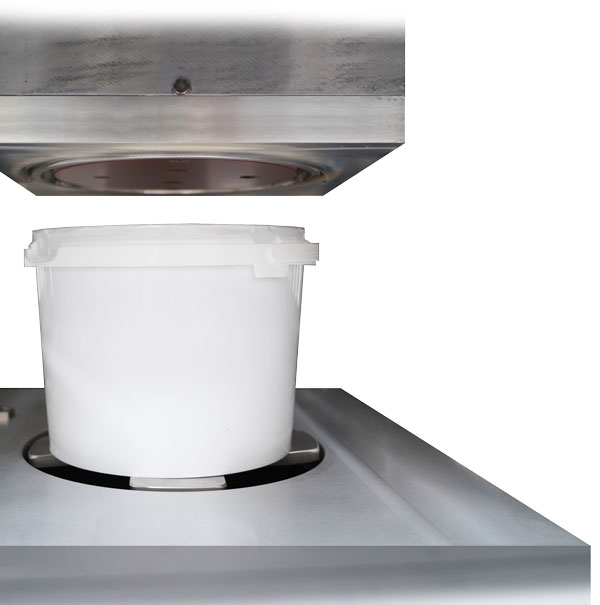

The FoodPack Speedy Buckets is designed to cater to medium to large-scale production environments that require efficient and reliable bucket packaging. With its substantial sealing area and ability to accommodate a wide range of container diameters, this machine offers flexibility and high productivity. The touch screen panel enhances user-friendliness and operational efficiency, while the bucket denester and snap-on lid denester streamline the packaging process. This machine is a perfect fit for businesses seeking to optimize their bucket packaging process with a high-performance and versatile solution.

Sealing

Gas Flush

MAP/ATP

Vacuum

Technical Data

Technical data: FoodPack Speedy Buckets

Dimensions: 287 x 98 x h 174 cm

Weight: 1300 Kg

Air consumption: 90 Nlt/Ciclo max

Sealing area: 380 x 330 x h 260 mm

Container diameter: from 80 to 270 mm

Videos

DETAILS

Enhance Production

Explore Compatible Machines

Complete your production line with our range of automated packaging solutions.

Request a Quote

Get in touch here with our team to request a free quote. Our expert team will help you configure the best solution for your production line.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.