Fill Seal 7000

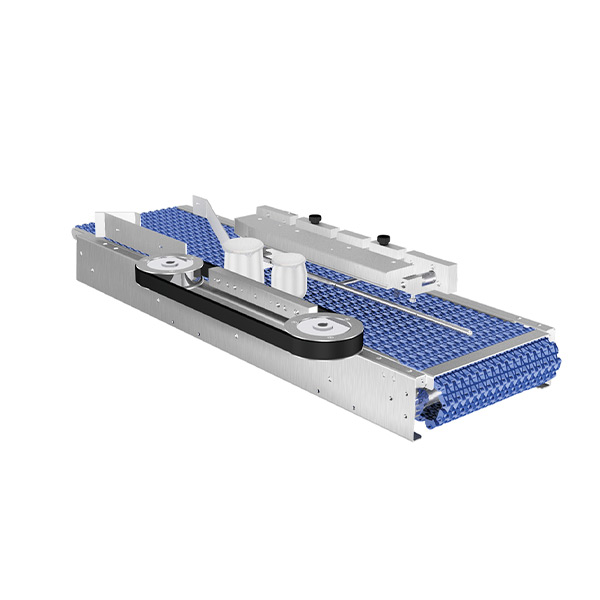

The Fill Seal 7000 is an advanced automatic filling and sealing machine, notable for its versatility in handling various product consistencies and container types, including plastic, paper, and aluminum.

It is designed for medium to large capacity production, making it a suitable choice for businesses looking to scale up their operations. The machine’s capability to dose several products simultaneously, even with different consistencies, sets it apart in the market. Additionally, its compatibility with a wide range of container materials demonstrates its adaptability to diverse packaging needs. The Fill Seal 7000 is also designed to integrate seamlessly with secondary packaging systems, offering a comprehensive solution for businesses seeking to streamline their entire packaging line.

High-Capacity Storage

Ensures maximum autonomy with an automatic infeed conveyor and large storage capacity, allowing for longer uninterrupted production runs.

Pick & Place

Automates the placement of pre-filled containers inside the machine, enhancing efficiency and reducing manual labour.

Suction of Foreign Materials

Removes foreign bodies from the bottom of containers, ensuring product purity and quality.

Ultra Cleaning System

Offers sanitization options like UVC lamps, pulsed light, and hydrogen peroxide for maintaining high hygiene standards.

Dosing Systems

Provides a variety of dosing options for precise and efficient filling.

Laminar Flow Hood

Supplies a constant flow of micro-filtered air inside the machine to increase product shelf life.

Crimping System

Crimps the lid to the side edge of glass or ceramic pots, ensuring a secure seal.

Inkjet Printer

Adds essential information like expiration dates and production lots to packaging for traceability.

CIP Clean-In-Place System

Enables autonomous washing of the dosing unit, ensuring thorough cleaning and sanitization.

Product Gallery

DETAILS