In Line

Fill Seal In Line

Full Description

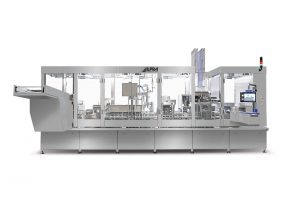

The ILPRA Fill Seal In Line 6L is a versatile and efficient solution for high-capacity packaging needs. It offers a range of packaging methods including sealing, gas flush, MAP/ATP, and vacuum.

The machine’s ultra-hygienic design ensures the integrity of the packaged product and facilitates maximum cleanliness. The total brushless configuration optimizes each work step, enhancing productivity and handling of products and containers. This line is perfect for businesses looking for a customizable, high-performance packaging solution that can adapt to various production demands.

- Sealing -

- Gas Flush -

- Vacuum -

- MAP/ATP -

Videos

Technology

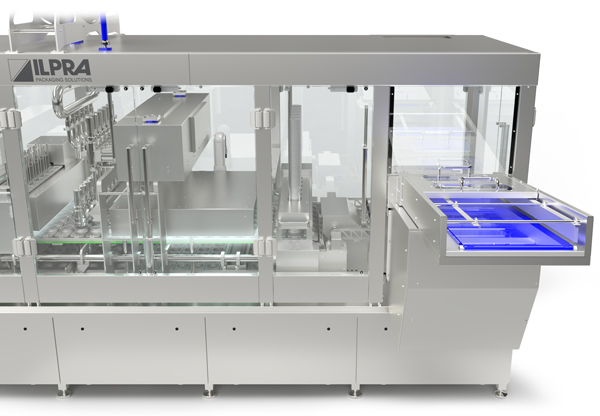

High-Capacity Storage

The machine features an automatic infeed conveyor and large capacity storage, which together guarantee maximum autonomy for both the machine and the operators. This station is designed to handle high volumes of packaging material, ensuring a continuous and uninterrupted production flow.

Cups Sanitization

This station employs UVC lamps, pulsed light, or hydrogen peroxide atomization to sanitize cups. The sanitization process is crucial for maintaining product safety and hygiene, especially in food and pharmaceutical packaging.

Dosing System

Serving as the heart of the entire machine, the dosing system is custom-designed according to the specific needs of the customer and the type of product to be packaged. This system ensures precise and consistent dosing, which is essential for product quality and standardization.

Pre-Cut Lids Denester

This station is responsible for the accurate placement of pre-cut lids on the pots. It is designed to guarantee maximum autonomy, reducing the need for frequent operator intervention and ensuring a smooth packaging process.

Pre-Cut Lids Sanitization

Similar to the cups sanitization station, this station uses UVC or pulsed light lamps to sanitize pre-cut lids, ensuring the reduction of any bacterial load. This step is vital for ensuring the overall hygiene of the packaging process.

Sealing Station

At this station, lids or films are sealed onto the pots. The high efficiency of this station is key to extending the product’s shelf-life by ensuring airtight and secure sealing.

Lids Storage

This station features a high-capacity storage system for lids, allowing for extended operation without the need for frequent reloading. The ample storage capacity ensures that the machine can operate autonomously for longer periods, enhancing productivity.

Cups Ejection

This station manages the orderly and regular exit of pots onto a fully washable belt. It is designed to integrate seamlessly with various accessories and secondary packaging systems that may be installed after this point.

Tray-Carrier Cleaning and Drying

Featuring an automatic washing system, this station is dedicated to the cleaning and drying of tray-carriers. It ensures that the carriers are hygienically maintained, which is crucial for the overall cleanliness of the packaging process.

DETAILS

Enhance Production

Explore Compatible Machines

Complete your production line with our range of automated packaging solutions.

Request a Quote

Get in touch here with our team to request a free quote. Our expert team will help you configure the best solution for your production line.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.