In Line

FoodPack 1450

Full Description

This machine is an effective in-line model that can simultaneously process three 187×137mm containers. Its flexibility is suited to a wide range of packaging applications, such as fruit, meat, ready meals, and fish.

The FoodPack 1450 is a high-performance, automatic in-line tray sealer, representing the ideal mix of dependability and flexibility for companies looking to enhance their packaging processes. Its design ensures seamless integration into current production setups, accommodating a broad spectrum of products thanks to its large sealing area and straightforward operation.

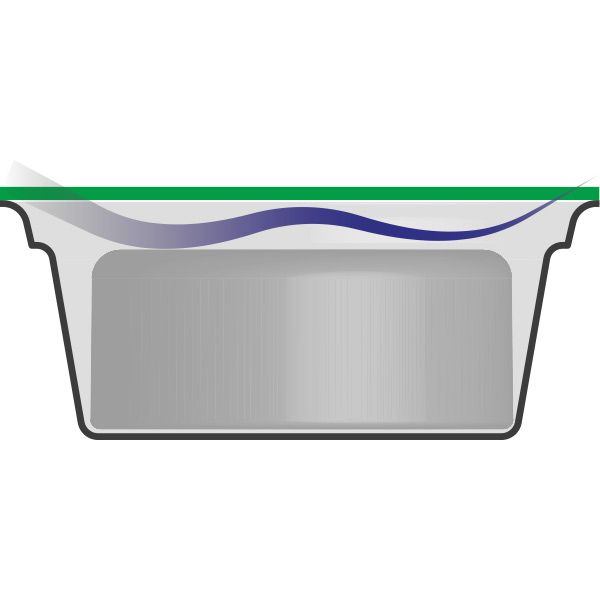

Gas Flush

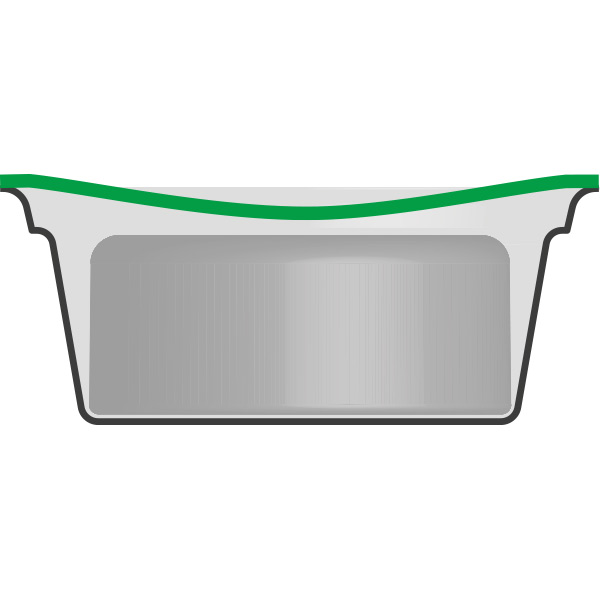

Vacuum

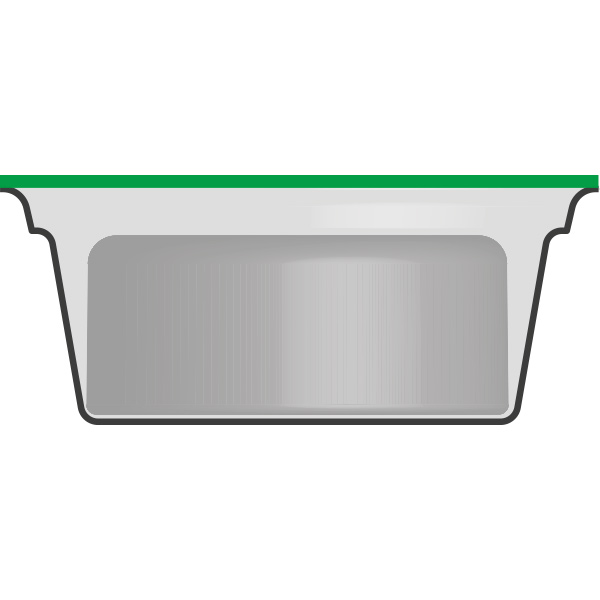

Sealing

MAP/ATP

Skin

Overskin

Extraskin

Extraskin on Cardboard

Technical Data

Technical Data : FoodPack 1450

Dimensions: 331 x 90 x h 190 cm

Weight: approx. 1100 Kg

Air Consumption: 6 bar - 5 Nlt/cycle

Sealing Area: 560 x 350 x h 120 mm

Videos

Technology

E-MEC TECHNOLOGY

Featuring fully electromechanical movement technology at the workstation, this boosts speed and productivity.

PROGAS SYSTEM

ILPRA’s patented innovation, the PROGAS System, cuts down on gas usage while boosting operational speed, and it’s a standard inclusion across this product line.

CONSTANT PLACEMENT SYSTEM

This sophisticated system ensures a steady tray supply into the machine, thanks to belt and jaw interpolation, which significantly raises production speed.

Optional: EXTRASKIN System

Allows for skin packaging at high protrusion levels, broadening packaging possibilities.

Optional: Pre-Heating System

Enhances skin packaging by pre-warming the film, boosting both packaging quality and efficiency.

Optional: Predictive Maintenance

An innovative system that plans maintenance and part replacements, increasing machine durability and dependability.

Optional: ID Control System

Improves security through badge recognition for identifying authorized staff, offering up to three tiers of access.

Optional: Anti-Crush System

Avoids tray damage by stopping the sealing process in case of misalignment, preserving the integrity of the product.

DETAILS

Enhance Production

Explore Compatible Machines

Complete your production line with our range of automated packaging solutions.

Request a Quote

Get in touch here with our team to request a free quote. Our expert team will help you configure the best solution for your production line.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.