In Line

FoodPack 1465

Full Description

This machine is crafted for smooth incorporation into current setups, providing high mold efficiency and rapid cycle times.

Featuring built-in CPS (Constant Placement System) technology, the FoodPack 1465 stands out in enhancing production with sophisticated synchronization between jaws and belts. Its adaptable design can be tailored to meet an array of packaging requirements, such as poultry, snacks, meat, ready meals, fish, and fresh produce.

Engineered for top efficiency and effortless integration, the FoodPack 1465 is an automatic in-line tray sealer that redefines packaging standards. Perfect for companies looking to upgrade their production capacity, it supports a wide variety of products with its large sealing area and easy-to-use functions. The machine’s dimensions and air usage are finely tuned for high volume operations, positioning it as an ideal option for sectors seeking to optimize both space and efficiency.

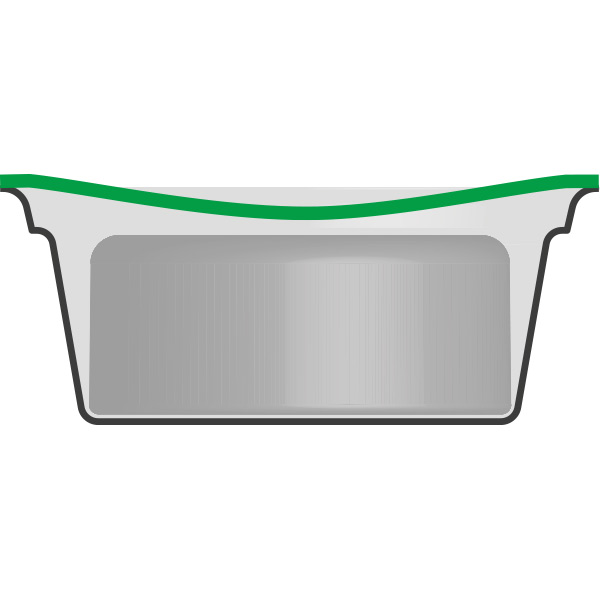

Gas Flush

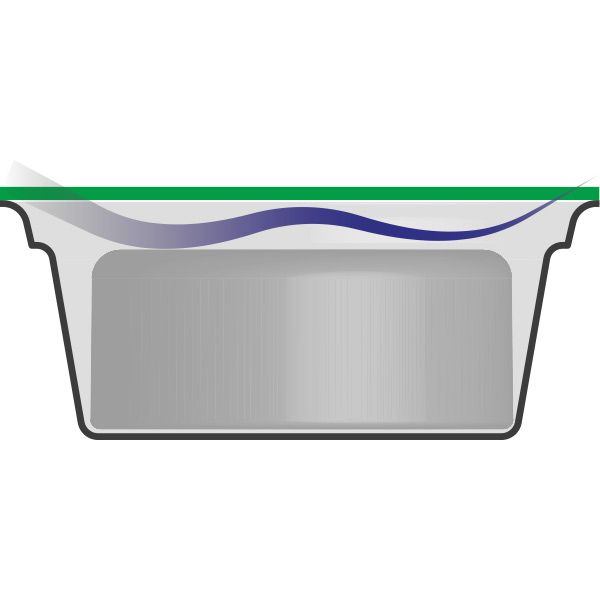

Vacuum

Sealing

MAP/ATP

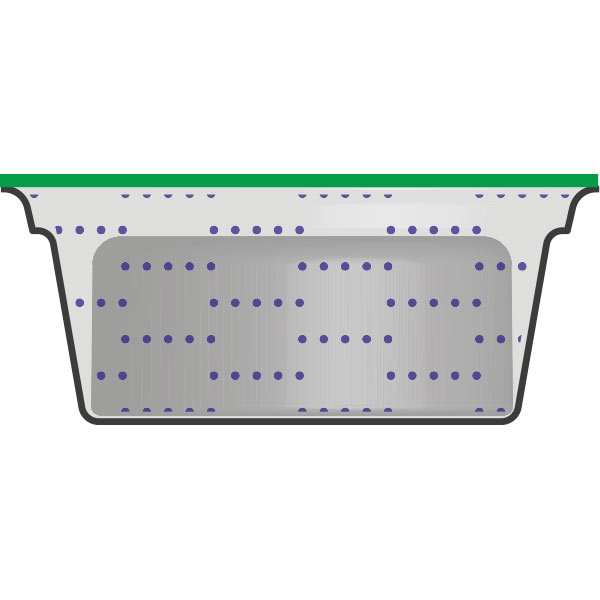

Skin

Overskin

Extraskin

Extraskin on Cardboard

Technical Data

Technical Data : FoodPack 1465

Dimensions: 342 x 90 x h 190 cm

Weight: approx. 1200 Kg

Air Consumption: 6 bar - 5 Nlt/cycle

Sealing Area: 680 x 350 x h 120 mm

Videos

Technology

E-MEC Technology

Utilizes completely electromechanical actions to boost speed and productivity, making operations more efficient.

ProGas System

ILPRA’s patented system reduces gas consumption and enhances operational velocity, standard on all models.

Constant Placement System

Advanced technology guarantees continuous tray movement, improving production pace with accurate synchronization between belts and jaws.

Optional: ExtraSkin System

Facilitates sophisticated skin packaging, accommodating high product protrusion to expand packaging capabilities.

Optional: Pre-Heating System

Heats film beforehand to enhance skin packaging effectiveness, resulting in a superior quality seal.

Optional: Predictive

Incorporates a maintenance planner that schedules service and parts replacement, improving machine reliability and uptime.

Optional: ID Control System

Employs a badge recognition system for employee verification, providing various levels of access control.

Optional: Anti-Crush System

Automatically identifies and adjusts for tray misalignment, pausing operations to avoid damage to products.

DETAILS

Enhance Production

Explore Compatible Machines

Complete your production line with our range of automated packaging solutions.

Request a Quote

Get in touch here with our team to request a free quote. Our expert team will help you configure the best solution for your production line.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.