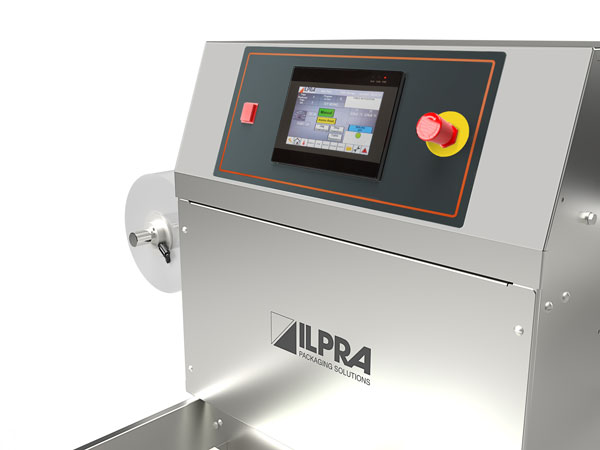

FoodPack 400 Extra Roto

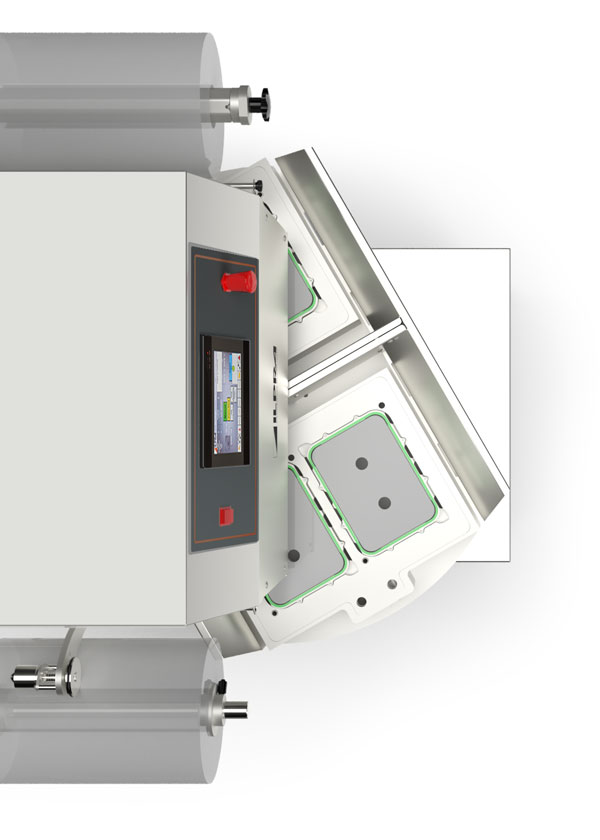

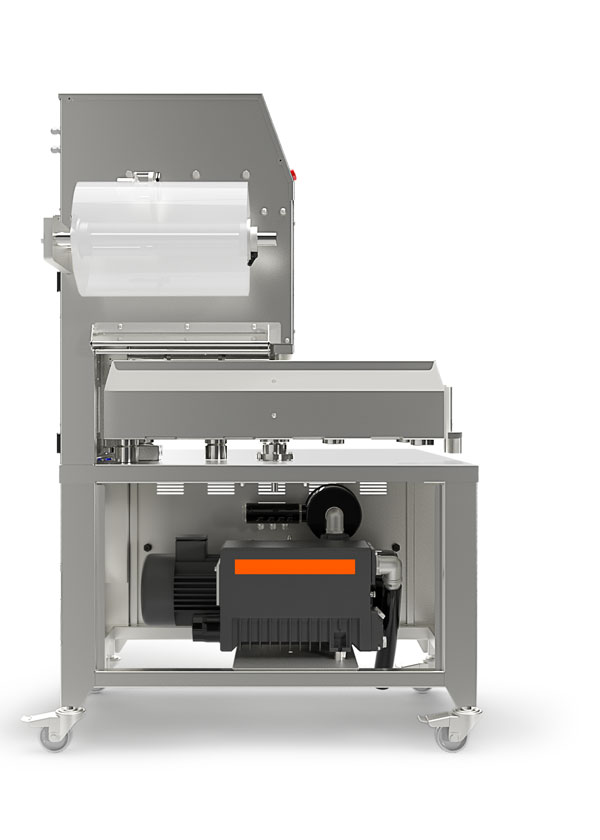

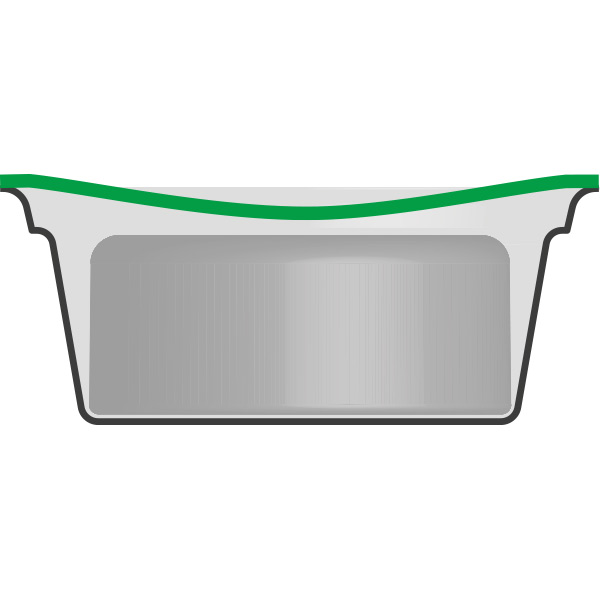

The FoodPack 400 Extra Roto combines user-friendly operation with a compact design, making it an ideal choice for small-scale operations. Its rotary table design significantly increases the yield of production by allowing simultaneous loading/unloading and sealing/cutting operations. This model is capable of handling up to six different types of packaging, including sealing only, MAP, vacuum, and various skin packaging methods, making it versatile for a range of product types. The integrated vacuum pump within the machine’s frame ensures a compact footprint, suitable for limited spaces.

PROGAS System

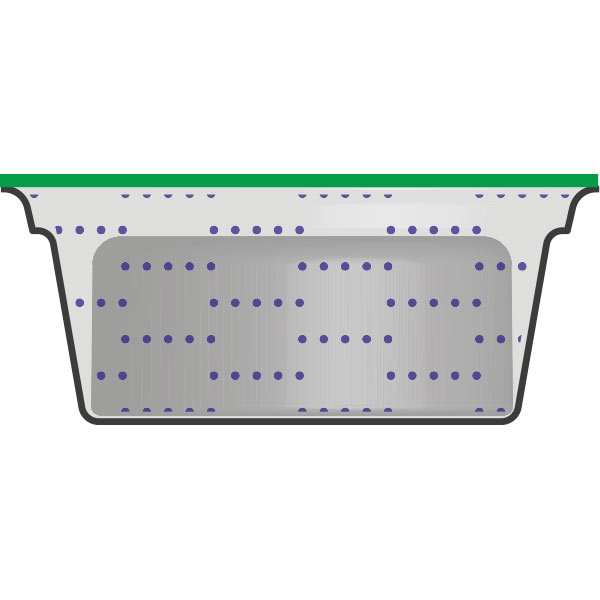

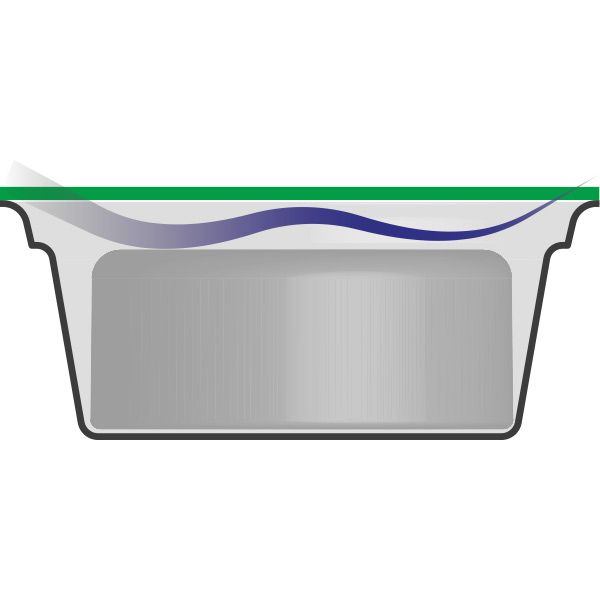

This patented technology by ILPRA optimizes gas usage and increases the speed of the packaging process, contributing to both cost savings and enhanced productivity.

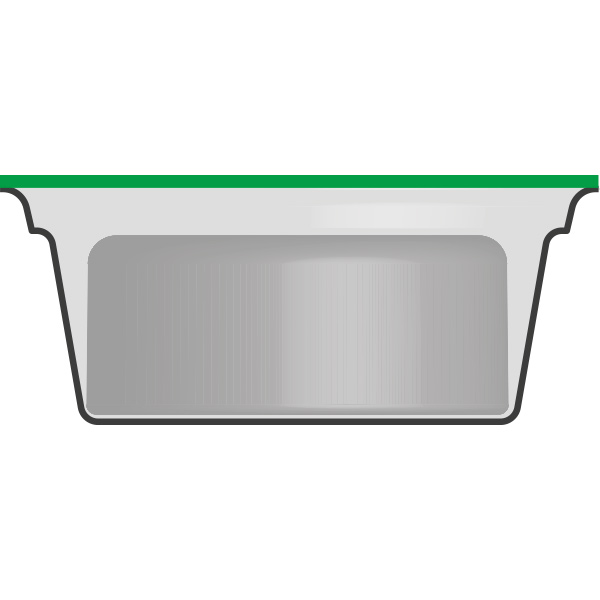

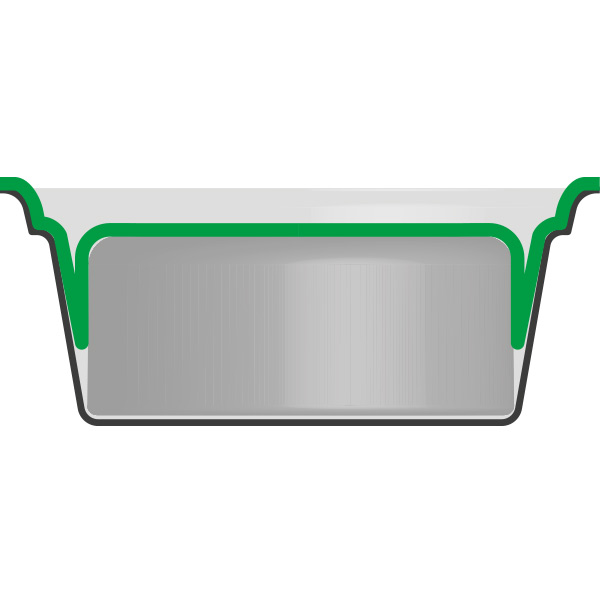

ExtraSkin

Specialized for high protrusion skin packaging, this technology allows for skin packing at up to 60 mm (optional 70 mm), providing flexibility and quality in packaging options, especially for products requiring enhanced presentation and protection.

Product Gallery

DETAILS