Semi-automatics

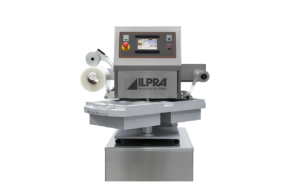

FoodPack Rotobasic

Full Description

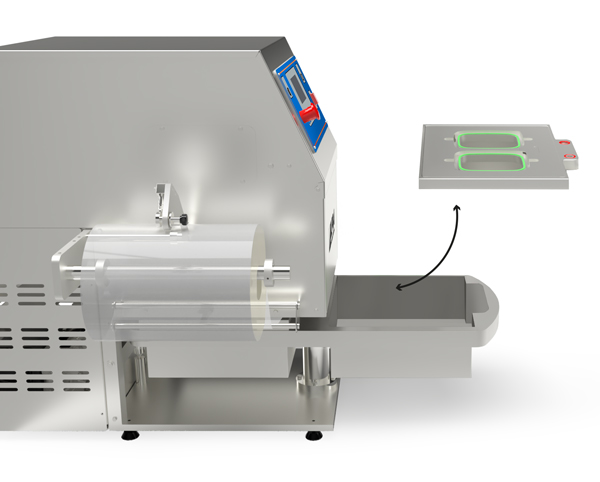

The FoodPack RotoBasic combines the compact and easy-to-use features of the FoodPack Basic with the added efficiency of a rotary table. This table allows for the loading and unloading of packed trays on one station while sealing and cutting operations are performed on another, significantly increasing production yield. The machine supports various packaging applications, including sealing, MAP/ATP, and vacuum. Its design is tailored for small-scale producers who need a reliable, efficient, and space-saving packaging solution.

This model is particularly effective for small production runs and is suitable for packaging a variety of food products such as pasta, meat, fish, and ready meals. The RotoBasic version features a rotary table, enhancing the efficiency of the packaging process.

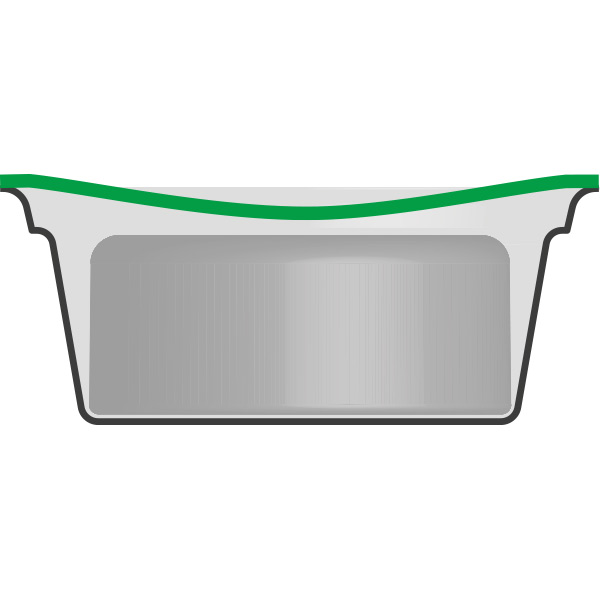

Sealing

MAP/ATP

Vacuum

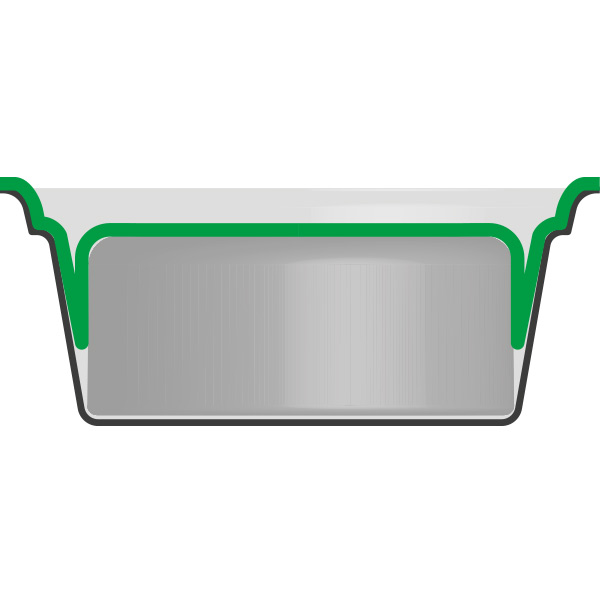

Skin

Technical Data

Technical Data:

Dimensions:

Weight :

Air Consumption :

Sealing area :

Technical Data: FoodPack Rotobasic

Dimensions: 104 x 87 x h 78 (N) - 116 x 87 x 78 (VG)

Weight : 130 (N) - 150 (VG) Kg

Air Consumption : 6 bar - 5 Nlt/cycle

Sealing area : 330 x 270 x h 135 mm

Videos

Technology

PROGAS System

The ProGas System, exclusively developed by ILPRA, represents a significant advancement in tray sealing technology. This system is ingeniously designed to optimize gas consumption during the packaging process, leading to substantial savings in gas usage.

DETAILS

Enhance Production

Explore Compatible Machines

Complete your production line with our range of automated packaging solutions.

Request a Quote

Get in touch here with our team to request a free quote. Our expert team will help you configure the best solution for your production line.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.