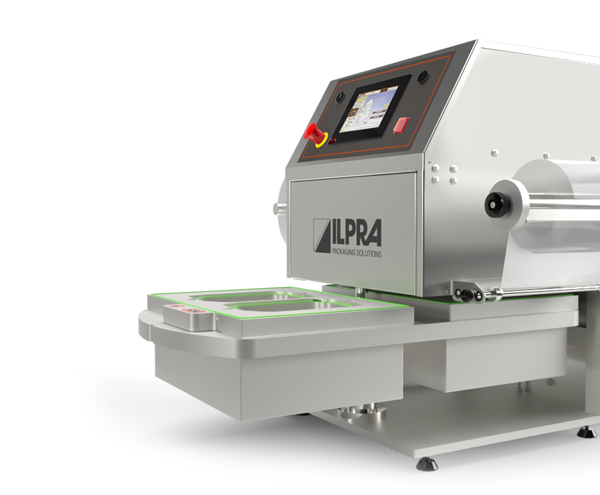

FoodPack Roto Energy

The FoodPack Roto Energy is an advanced solution for businesses seeking enhanced packaging capabilities. It features an enhanced sealing cylinder for greater sealing power and a larger sealing area to accommodate bigger trays, making it suitable for more demanding packaging tasks. The rotary table design of the Roto Energy version significantly boosts productivity by facilitating continuous operation without downtime for loading and unloading.

This model supports various packaging applications, including sealing, MAP/ATP, vacuum, and skin packaging, and is ideal for businesses that require a higher output without compromising on packaging quality.

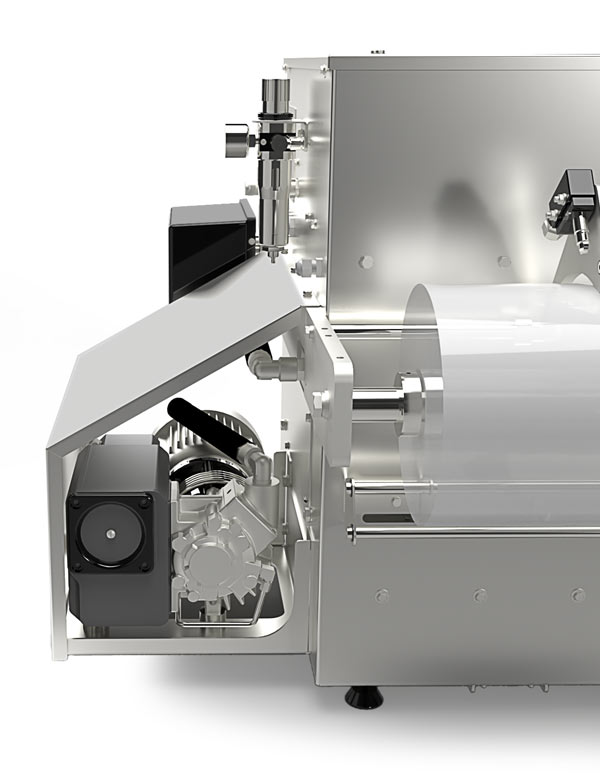

PROGAS SYSTEM

Technology patented by ILPRA that guarantees a lower use of gas and a higher working speed.

Available on all models in this line.

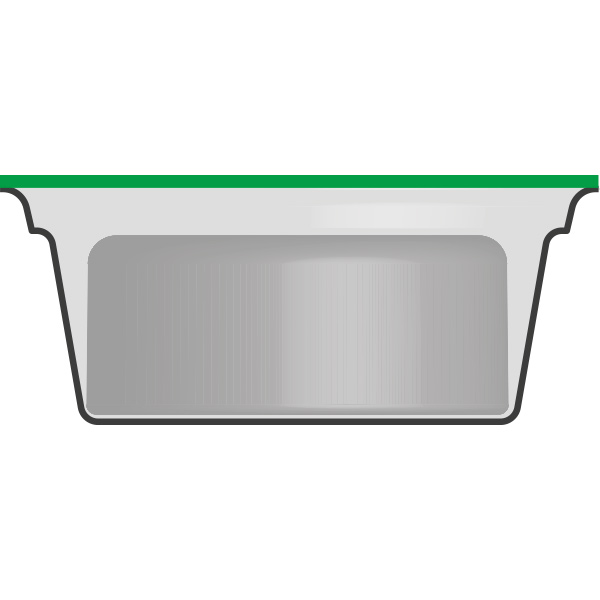

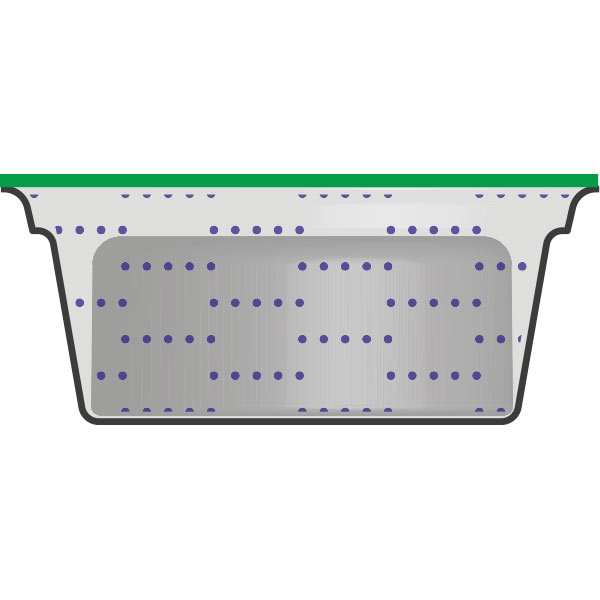

Product Gallery

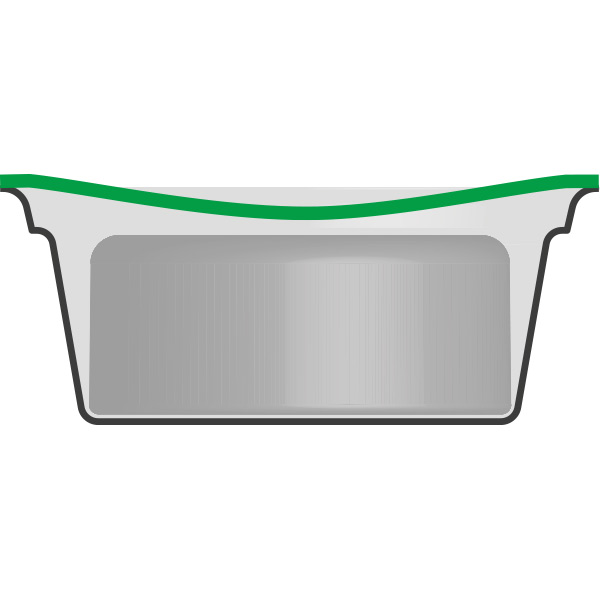

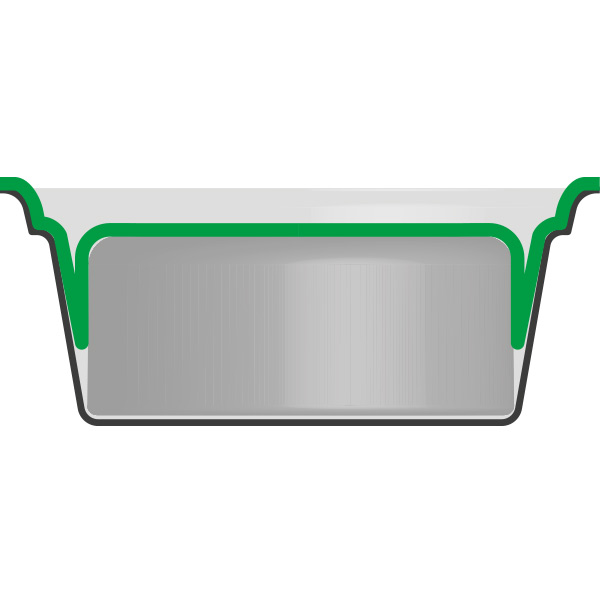

DETAILS