Automatics

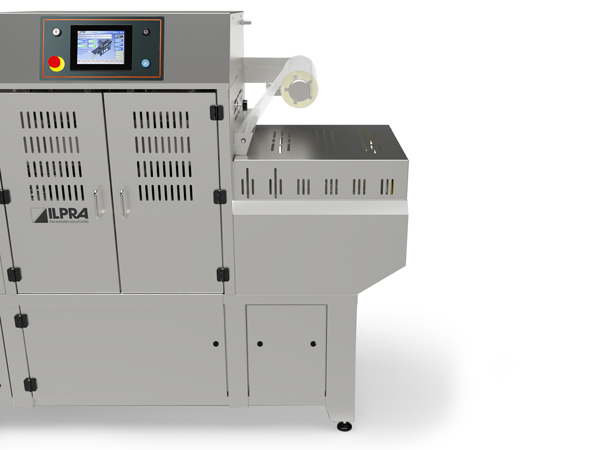

FoodPack Speedy Duo

Full Description

The Speedy Duo stands out for its ability to eliminate the need for mould changes, thereby saving time and increasing productivity. The machine is designed for versatility, supporting various packaging applications such as sealing, gas flush, MAP/ATP, vacuum, and different types of skin packaging. Its large loading area, activated by servo motors, can be adjusted for speed, acceleration, and deceleration, with an option to add a third step for even greater load capacity.

The touch screen panel controls all working parameters and stores different recipes for quick use, also providing access to a self-diagnostic system for efficient problem-solving.

Sealing

Gas Flush

MAP/ATP

Vacuum

Skin

Overskin

Extraskin

Extraskin on Cardboard

Technical Data

Technical Data : FoodPack Speedy Duo

Dimensions: 323 x 103 x h 158 cm

Weight: approx. 800 Kg

Air Consumption: 6 bar - 70 (N) 75 (VG) Nlt/cycle

Sealing Area: 380 x 270 x h 135 mm

Videos

Technology

PROGAS System

This patented technology by ILPRA ensures lower gas usage and higher working speed, available across all models in this line.

Optional: ExtraSkin System

This system allows for advanced Skin packing, even at high degrees of protrusion, offering enhanced packaging options that cater to a variety of product shapes and sizes.

Optional: Pre-Heating System

The Pre-Heating System optimizes Skin packaging by pre-heating the film, which enhances the packaging quality and efficiency. This system is particularly beneficial for ensuring a smoother and more consistent skin packaging process.

DETAILS

Enhance Production

Explore Compatible Machines

Complete your production line with our range of automated packaging solutions.

Request a Quote

Get in touch here with our team to request a free quote. Our expert team will help you configure the best solution for your production line.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.