Automatics

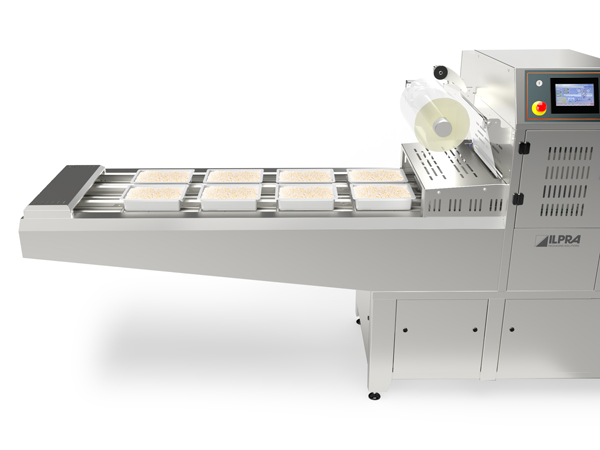

FoodPack Speedy XL E-mec

Full Description

The FoodPack Speedy E-Mec stands out for its mechanical design, which ensures silent and efficient operation, making it suitable for a variety of packaging environments. The wider sealing area enhances its capability to handle larger or multiple items, increasing its applicability. The color touch screen interface is simple and intuitive, making the machine user-friendly and easily operable, even for those with minimal experience. This model is ideal for businesses looking for a reliable and efficient packaging solution that combines ease of use with high performance.

Sealing

Gas Flush

MAP/ATP

Vacuum

Skin

Overskin

Extraskin

Extraskin on Cardboard

Technical Data

Technical Data: FoodPack Speedy E-mec

Dimensions: 323 x 116 x h 159 cm

Weight: approx. 800 Kg

Air consumption: 6 bar - 40 Nlt/cycle

Sealing area: 500 x 270 x h 135 mm

Videos

Technology

E-MEC Technology

The Speedy E-Mec incorporates a cutting-edge electromechanical technology that drives the working station. This innovation is key to achieving greater speeds and enhancing overall productivity.

PROGAS System

ILPRA’s ProGas System is a hallmark of their commitment to efficiency and sustainability. This system is engineered to use gas more judiciously during the packaging process, significantly lowering gas consumption.

Optional: ExtraSkin System

The ExtraSkin System is an optional feature that elevates the capabilities of the Speedy E-Mec, allowing it to perform advanced Skin packaging. This system is adept at handling high degrees of protrusion, making it ideal for packaging products that require a tight and secure seal.

Optional: Pre-Heating System

The optional Pre-Heating System is designed to optimize the Skin packaging process. By pre-heating the film, this system ensures a more uniform and effective seal, enhancing the packaging’s aesthetic and protective qualities.

DETAILS

Enhance Production

Explore Compatible Machines

Complete your production line with our range of automated packaging solutions.

Request a Quote

Get in touch here with our team to request a free quote. Our expert team will help you configure the best solution for your production line.

Get in touch

Speak to one of our experts

Get in touch with our team for tailored advice on which packaging solution is right for your products.