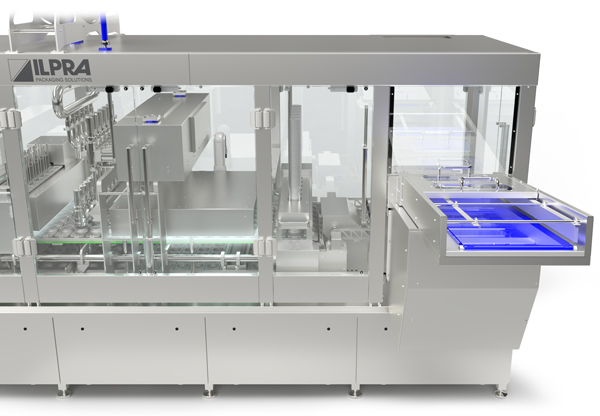

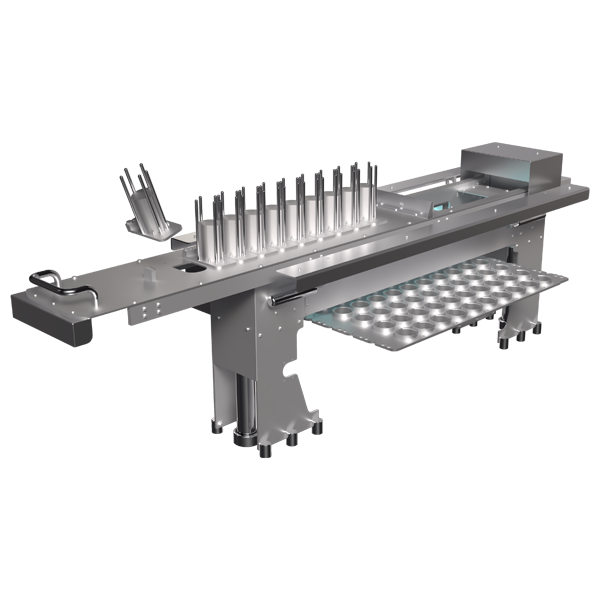

L Series

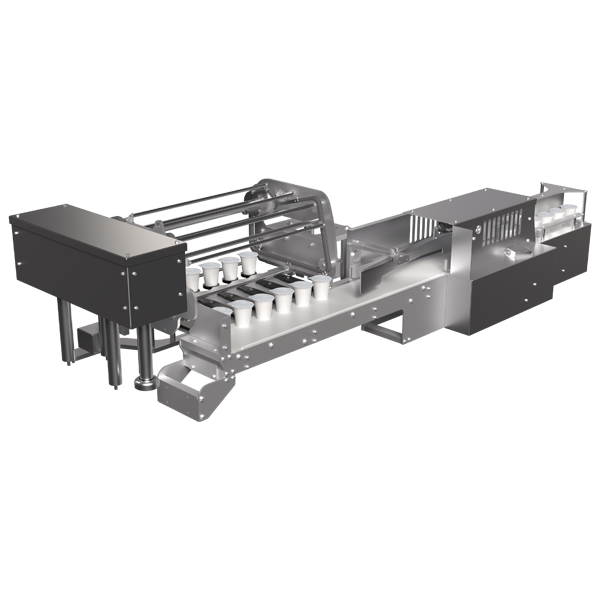

The Fill Seal Series L range is a modular platform for large-scale production, confi gurable by packaging type and output capacity. It ensures precise material handling

and optimized cycle times; its modularity allows accessory integration along the line. It’s compatible with cups of various materials, shapes, and sizes, provides quick format changeovers, and features servo-assisted stations for comprehensive control. It can be integrated with material sanitization systems to achieve ultra-clean packaging, particularly suited to dairy applications. Software with recipe management and advanced diagnostics reduces setup, downtime, and operating costs, contributing to high OEE.

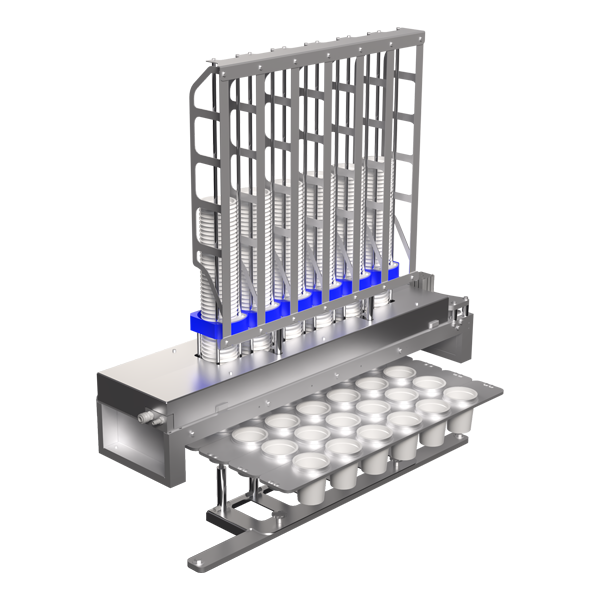

High-Capacity Storage

Thanks to the automatic infeed conveyor and the large capacity storage, this station guarantees the maximum autonomy of both machine and operators.

Cups Denester

Automatic system designed to feed cups continuously and accurately.

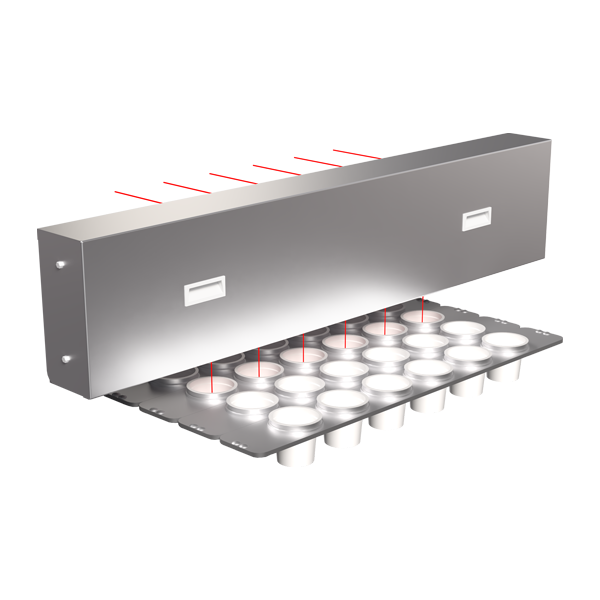

Cups Sensors

High-precision detection device for correct cup presence verifi cation, double denesting detection, and in-machine container recognition, ensuring a safe production flow.

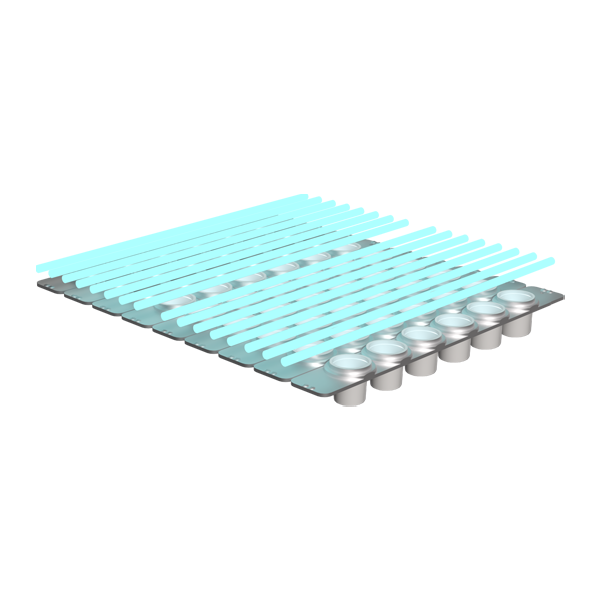

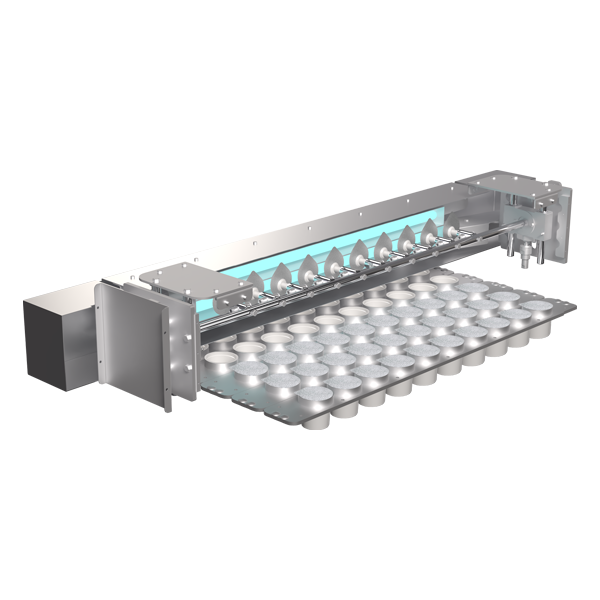

Cups Sanification

Realized through UVC lamps and/or pulsed light or by nebulization of hydrogen peroxide.

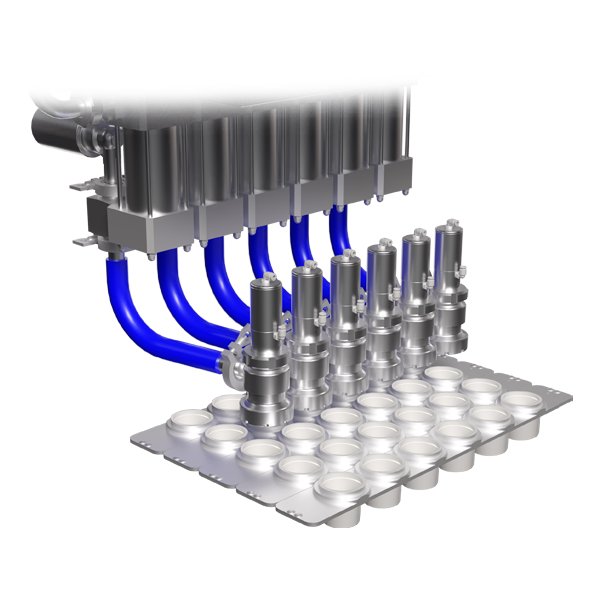

Dosing System

The dosing system is the heart of the entire machine. It is designed according to the specific needs of the customer and the type of product to be packed.

Pre-cut Lids Sanification

Realized through UVC lamps and/or pulsed light.

Pre-cut Lid Denester

Automatic disc-feeding unit with a buffer magazine for continuous loading without line stoppage, featuring a quick-release drawer system with tool-free, removable individual magazines for ultra-fast changeovers.

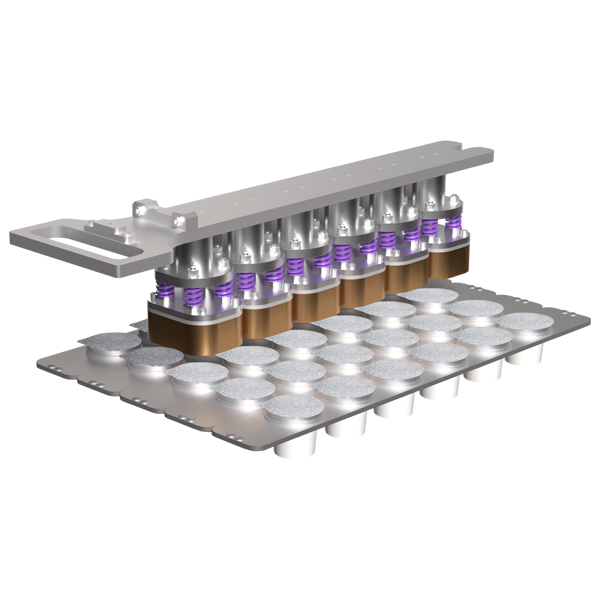

Sealing Station

Pneumatic or electronic sealing of the disk/film; simplified maintenance and format change thanks to drawer systems and a quick-change sealing head.

Cups Ejection

Lifts jars and transfers them to the outfeed conveyor using rotating rods, ensuring continuous flow and precise alignment.

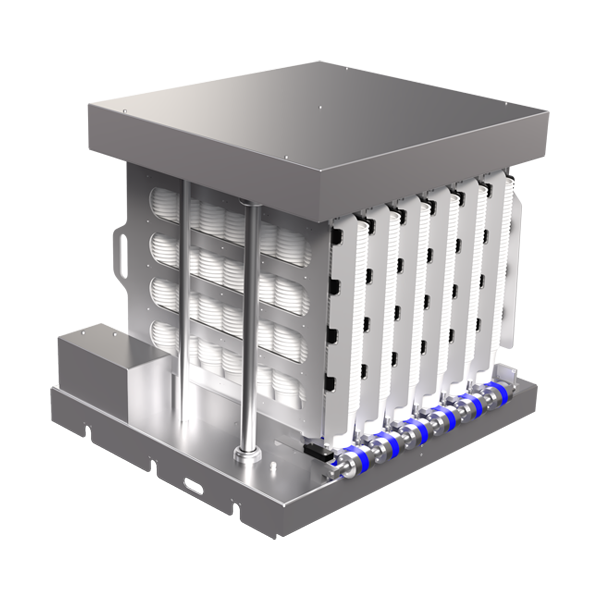

CIP Hopper

Available in multiple types according to machine configuration and end-user requirements: AISI 316 stainless-steel construction, spray ball for CIP cleaning, product level probes, optional insulation and heating.

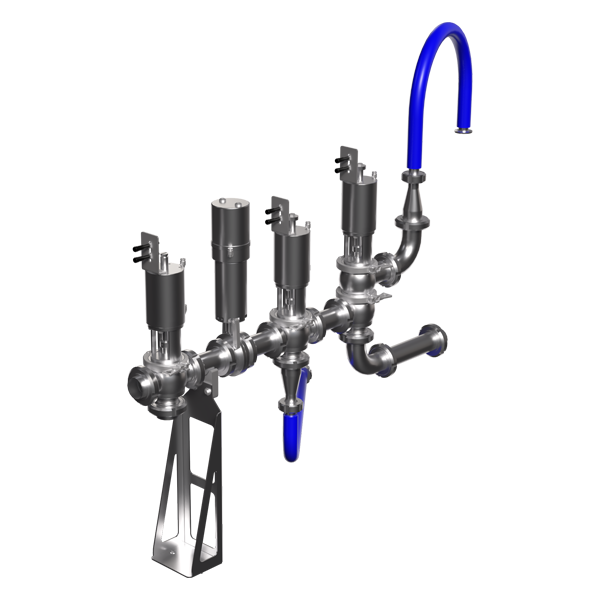

CIP Valve System

Pneumatic valve group controlled by PLC for setting washing recipes of the dosing unit.

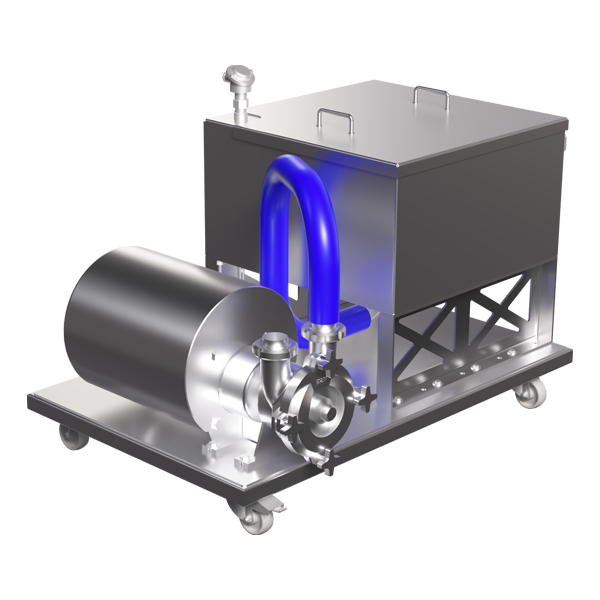

CIP Relaunch System

Unit designed to recirculate cleaning solutions within the CIP system, ensuring constant pressure and optimal flow for effective equipment sanitization.

Product Gallery

DETAILS